Case Study: Box Furnace Project

This project was a box style furnace for investment casting of wax, SLA (sterolithography), and other Rapid Prototyping techniques. The customer had two burnout/preheat furnaces but were having difficulties meeting the demands of a growing company as well as changing specifications. The two existing furnaces were found to be extremely inefficient with the way they delivered heat to the product which resulted in poor production rates and unnecessary scrap. The single new furnace was able to replace the existing two furnaces’ production rates as well as meting all of the demands of Rapid Prototyping. The new furnace system incorporates the following features:

- Controlled at either 6% or 12% oxygen levels through the flip of a switch

- Temperature uniformity complying with AMS2750 Revision E guidelines of +/- 25°F between 1800°F and 2100°F

- Recuperative combustion reducing fuel consumption by 38% at 6% oxygen levels

- Without recuperative combustion, 12% oxygen levels at 2100°F is not practical

- Integral afterburner providing complete incineration of all waste satisfying all emission guidelines

- Insitu oxygen monitoring

- Bypass temperature control allowing the removal of the flame supervision network from the safety logic when the furnace is over 1400°F, as provided for in NFPA 86 (National Fire Protection Association’s Standard for Furnaces and Ovens). This eliminates the potential for nuisance shutdowns

- Minimized inside floor space by placing the afterburner and recuperator outside, allowing for easy expansion should production continue to increase.

Please view the galleries below to see the production and installation process.

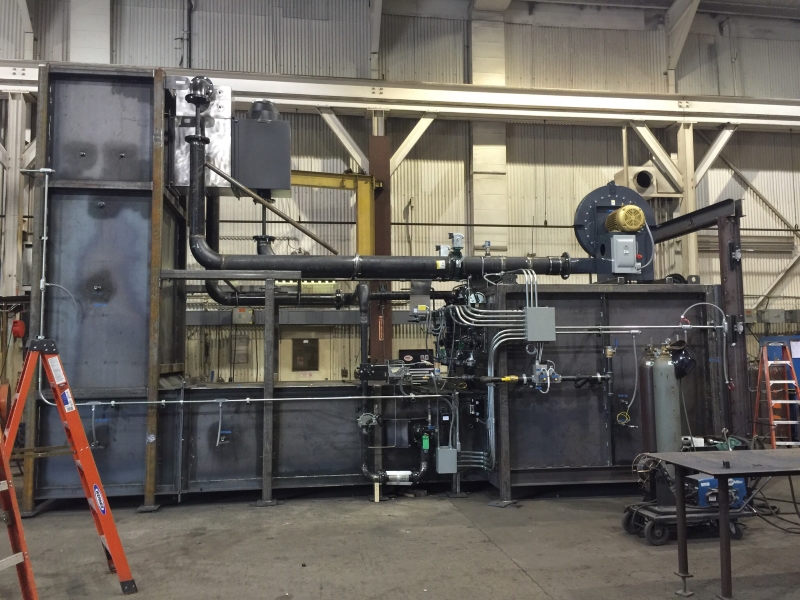

Fabricated, insulated, piped, wired and tested prior to shipment

As received at the customer’s location. Packaging considerations were taken into account for easy re-assembly, reduced shipping costs and moving the unit through the aisles in the facility.

Installation progression. This furnace systems’ floor space was minimized in many ways. One way was to place the afterburner and recuperator outside. This allows for easy installation of a second furnace should production demands continue to grow.

Completed insulation package including corrugated hearth, brick curb and fiber walls/roof providing skin temperatures below 130°F with operating temperatures of 2100°F

Easy to operate control panel provided with a remote door operation.

This control panel provided easy access to information such as process temperature control, afterburner temperature control, recuperator temperature control, pressure control and oxygen level control with ethernet communication for a central SCADA package allowing for recipe management and data acquisition.